Ethylene Propylene Rubber, commonly referred to as EPDM. This material is often used in hot water steam applications as well as in fire resistant fluids where synthetic oils are used. EPDM materials are also used in bases, acids and alcohols. EPDM is also used for brake fluids, but we recommend to observe local safety-regulations before installing an EPDM seal in breaking systems. EPDM is not resistant to mineral, vegetable and animal oils.

EPDM products are also available with FDA grade in white colour, which is approved for usage in applications contact with foodstuffs.

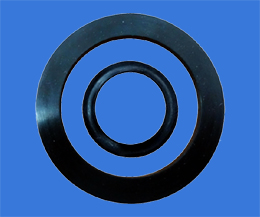

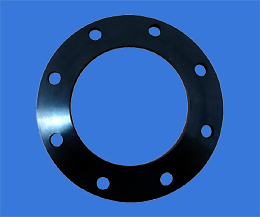

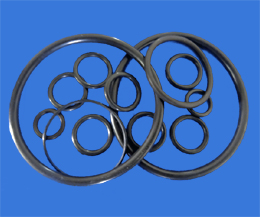

Static and Dynamic seals, wipers, O-rings, Gaskets, Flange seals, rotary seal, rubber energisers. Cleaning and washing technology; Applications in food industry.

| Density | DIN 53479 | g/cm3 | 1.22 |

| Hardness | DIN 53505 | Shore A | 85 |

| Tensile strength | DIN 53504 | N/mm2 | 12.8 |

| Elongation at Break | DIN 53504 | % | 130 |

| Modulus 100% | DIN 53504 | N/mm | 6.2 |

| Tear Strength | DIN 53507B | N/mm | 3.2 |

| Compression Set: 70h/RT | DIN 53517A | % | 20.9 |

| Compression Set: 22h/70°C | DIN 53517A | % | 20.7 |

| Compression Set: 22h/100°C | DIN 53517A | % | 19.8 |

| Compression Set: 22h/150°C | DIN 53517A | % | 40.9 |

| Min. service temperature | °C | -50 | |

| Max. service temperature | °C | 130 |

| Density | DIN 53479 | g/cm3 | 1.39 |

| Hardness | DIN 53505 | Shore A | 85 |

| Tensile strength | DIN 53504 | N/mm2 | 7.3 |

| Elongation at Break | DIN 53504 | % | 374 |

| Modulus 100% | DIN 53504 | N/mm | 4.2 |

| Tear Strength | DIN 53507B | N/mm | 5.8 |

| Compression Set: 70h/RT | DIN 53517A | % | 22.3 |

| Compression Set: 22h/70°C | DIN 53517A | % | 45.1 |

| Compression Set: 22h/100°C | DIN 53517A | % | 77.9 |

| Min. service temperature | °C | -50 | |

| Max. service temperature | °C | 100 | |

| Short time max. service temp. In Air | °C | 130 |

Key to chemical resistance: R=Resistance S-Suitable U=Unsuitable

The mentioned properties are only valid for test pieces of the corresponding ISO, Din, and ASTM standards. They cannot be directly related to seals, gaskets and other sealing products and should be used only as a general guide. Customer required properties for the Rubber materials can be produced and analysised.