Nitrile Butadiene Rubber commonly referred to as NBR, Nitrile or BUNA. Good physical characteristics and chemical resistance to the most common hydraulic fluids makes NBR an excellent sealing material. NBR materials are one of the most used elastomers in sealing applications.

NBR products are also available with FDA grade in white colour, which is approved for usage in applications contact with foodstuffs.

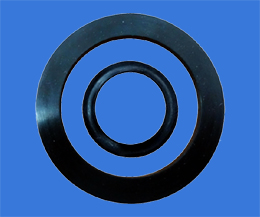

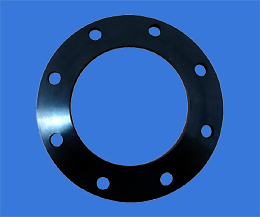

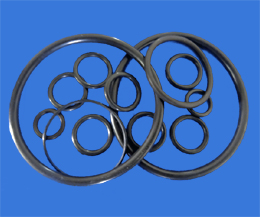

Static and Dynamic seals, wipers, O-rings, Gaskets, Flange seals, rotary seal, rubber energisers. Applications in food industry.

| Density | DIN 53479 | g/cm3 | 1.32 |

| Hardness | DIN 53505 | Shore A | 85 |

| Tensile strength | DIN 53504 | N/mm2 | 17.2 |

| Elongation at Break | DIN 53504 | % | 171 |

| Modulus 100% | DIN 53504 | N/mm | 10.2 |

| Tear Strength | DIN 53507B | N/mm | 3.3 |

| Compression Set: 70h/RT | DIN 53517A | N/mm | 6.0 |

| Compression Set: 22h/70°C | DIN 53517A | % | 6.7 |

| Compression Set: 22h/100°C | DIN 53517A | % | 6.8 |

| Min. service temperature | °C | -25 | |

| Max. service temperature | °C | 100 |

Key to chemical resistance: R=Resistance S-Suitable U=Unsuitable

The mentioned properties are only valid for test pieces of the corresponding ISO, Din, and ASTM standards. They cannot be directly related to seals, gaskets and other sealing products and should be used only as a general guide. Customer required properties for the rubber material can be produced and analysised.